![]() Dartmouth’s Thayer School of Engineering has a long running tradition that requires students enrolled in ENGS 25: Introduction to Thermodynamics to create and fully assemble a functional Stirling Engine. Over the course of 8 weeks, students report to the machine shop weekly and build different parts of their engine from scratch. At the end of the term, each engine is tested for rpm and efficiency.

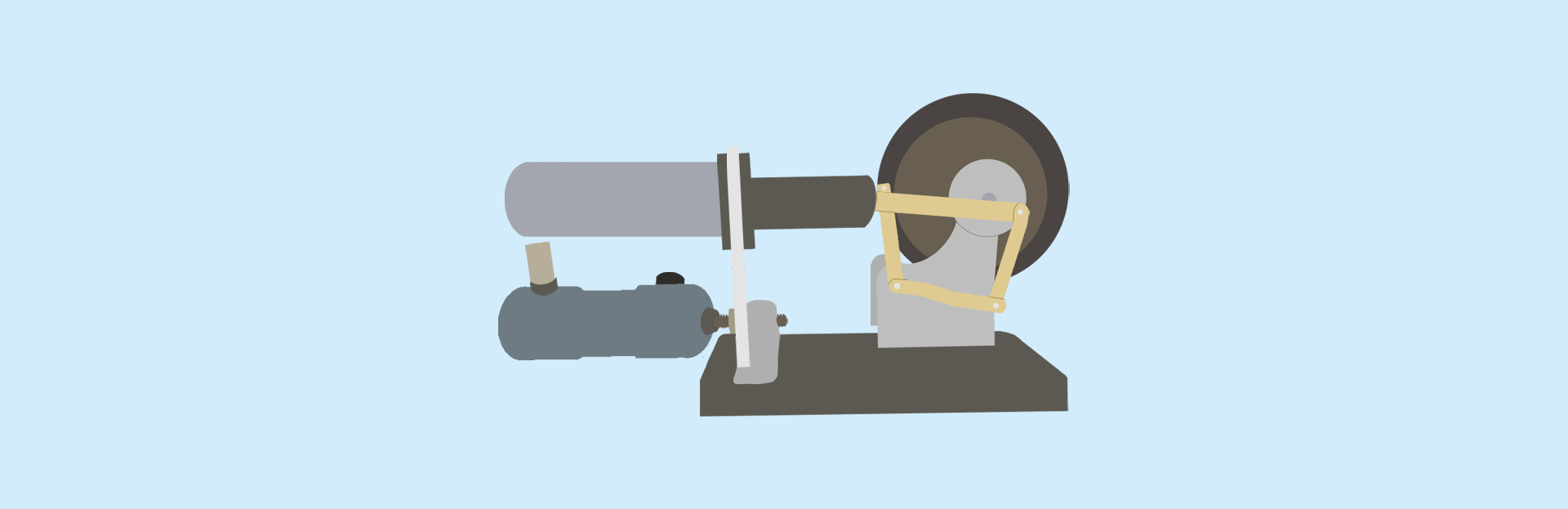

Dartmouth’s Thayer School of Engineering has a long running tradition that requires students enrolled in ENGS 25: Introduction to Thermodynamics to create and fully assemble a functional Stirling Engine. Over the course of 8 weeks, students report to the machine shop weekly and build different parts of their engine from scratch. At the end of the term, each engine is tested for rpm and efficiency.

Project Goals

For this project, I had two goals at the outset. I wanted to learn the basics of operating a variety of tools in the machine shop and I wanted to have a running engine by the end of the allotted time. If those seem like simple & easily doable goals… you definitely didn’t know me at the beginning of July 2017.

Process & Result

Entering the class, I didn’t have very high hopes hopes for my engine… I had never seen a mill or a lathe and I certainly didn’t know how to use a drill press. However, after having the right exposure to the shop equipment and peer guidance throughout the term, I was able to successfully assemble my engine. After a few mishaps (some parts sticking together from acute rust), my engine was able to generate 650 rpm. The class’ top three rpms were as follows:

First: 907

Second: 755

Third: 707

… 650 wasn’t too shabby for someone who had previously never stepped foot in the machine shop.

Project Takeaways

Machine Shop Skills ✓ | Functional Engine ✓

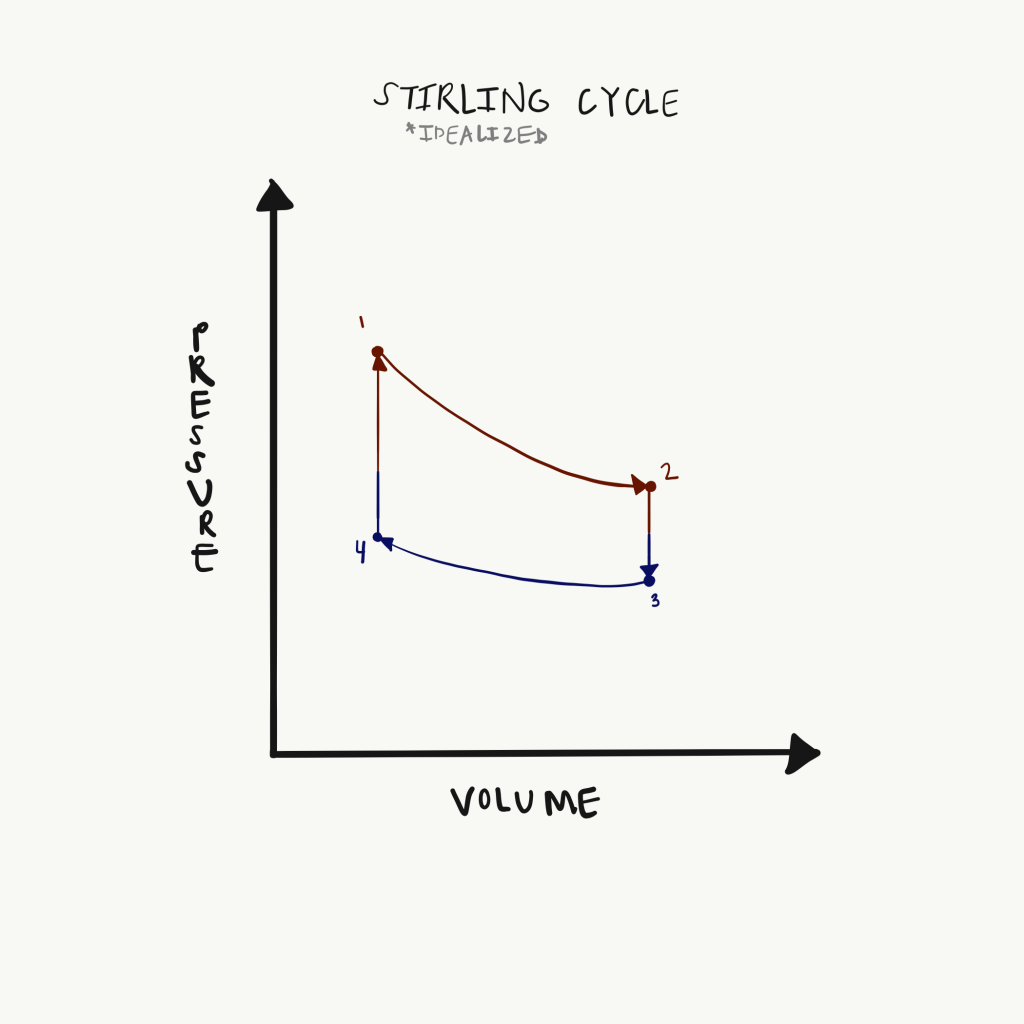

Although we were given basic instruction on how to assemble our engines, being successful required reasonable understanding of the thermodynamic concepts behind it. Each individual part of my engine solicited questions of how it [specifically] fit into the system as a whole. Thus, I adopted an applied understanding of the Stirling Cycle and was able to see its use in real-time; effectively bringing seemingly abstract classroom concepts to life.

The process of constructing each part of my engine was key for me in gaining not only machine shop skills, but also confidence in my overarching engineering capabilities. When the term finished and my engine started spinning, I finally got that feeling of “I’m an engineer.” The feeling that helped push me further into my engineering studies.